Foam is usually prepared immediately before injection by agitating a sclerosant with a gas using 2 syringes and a three-way tap. This is described as the Tessari method. A disadvantage of this foam preparation is its lack of stability. This is because, after a few minutes, the bubbles coalesce into larger bubbles which will decrease its efficacy and may cause safety concerns. A frother system has been proposed as a way of improving the stability of foam by increasing the half-life of the created micro-bubbles.

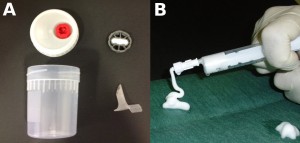

ENRIC ROCHE Our method consists of creating a froth using a sterile container and a magnetic stirrer. The lid contains a valve which allows the introduction of the sclerosant and gas of choice. Once activated the stirrer rotates under adjustable high speeds to produce the froth. On completion, the lid is opened and the froth is aspirated into a silicon free syringe. This is then injected into the target vein using a needle via a 5 micron filter.

We have used this system with various gases (air, O2/CO2 at 50/50) and polidocanol sclerosant at 0.5% and 2% concentrations. Foam stability was tested by visualising the bubbles under a microscope and photographing them at one minute intervals. Measurements demonstrated that the foams prepared with the frother system were more stable than those prepared using the Tessari technique and had a smaller average bubble volume. Furthermore, air was more stable than O2/CO2 and 2% polidocanol was more stable than the 0.5% concentration. We propose that the use of the frother system is a step closer towards standardising foam preparation.

A) Sterile container, lid, magnetic stirrer and introducer B) Resulting foam